-

What Is a Flatbed Semi-Trailer and How Does It Work? Definition and Structural Design A Flatbed Semi-Trailer is a type of transport vehicle commonly used for the transportation of large, heavy, and ir...

READ MORE -

From massive construction projects to cross-country logistics, the role of reliable hauling equipment is more vital than ever. One vehicle that stands out in this arena is the Heavy Duty Trailer, a po...

READ MORE -

When it comes to moving large loads or transporting heavy equipment, a Heavy Duty Trailer is an indispensable tool in the transportation industry. Whether for construction, mining, or long-haul shippi...

READ MORE -

What is a flatbed semi-trailer, and how does it differ from a regular trailer? A flatbed semi-trailer is a simple, open-platform vehicle. Its key feature is the lack of fixed side panels and a roof, r...

READ MORE

What are the differences between Lowloader trailers and regular trailers?

In modern logistics and transportation, trailers are essential tools and play a crucial role. A wide variety of trailer types exist, tailored to different transportation needs. Lowloader trailers and regular trailers are the two most common types. Although both are used to transport bulky goods, they differ significantly in design, usage scenarios, load capacity, and technical features.

Design and Structural Differences

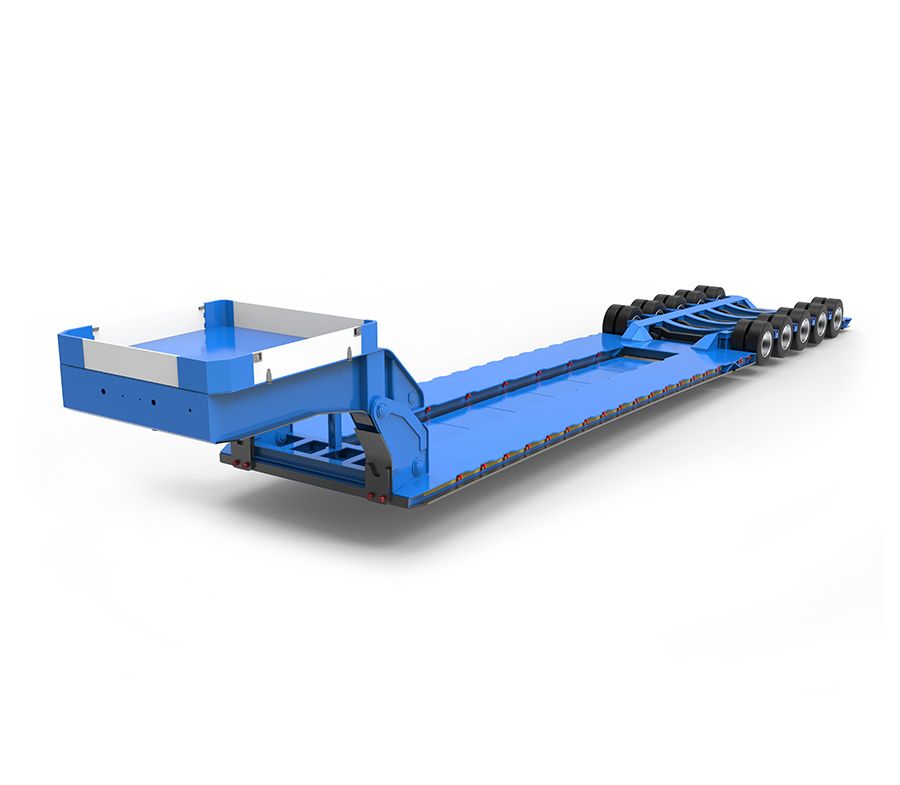

The biggest difference between Lowloader trailers and regular trailers lies in their body design. Lowloader trailers feature a low-platform design, meaning the cargo bed is lower to the ground. Regular trailers have a relatively high bed. The low center of gravity of Lowloader trailers enables them to transport tall equipment or machinery, such as construction machinery and wind turbine equipment.

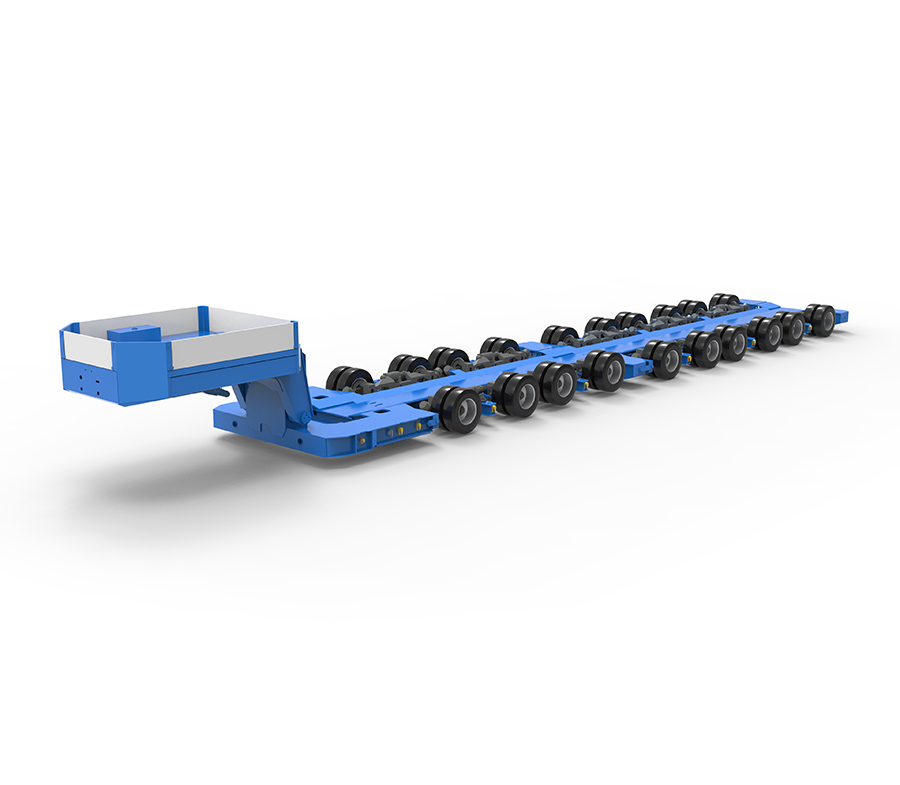

Lowloader trailers typically include multi-axle configurations, such as multi-axle steering and hydraulic suspension, which ensure they maintain a stable ride even when loaded. Regular trailers typically utilize standard single or dual-axle configurations and are suitable for general cargo transport. Hangzhou Kotter Intelligent Manufacturing Co., Ltd., a company specializing in the research and development and production of specialized vehicles, understands the importance of Lowloader trailer structures to transport efficiency. The company's product portfolio includes a variety of heavy-duty trailers, including Lowloader trailers with hydraulic suspension systems, which offer customers enhanced transport safety and stability, particularly when transporting overweight or oversized cargo.

Load Capacity and Stability

Lowloader trailers are designed specifically for transporting heavy or oversized cargo. Therefore, they typically offer greater load capacity and improved stability. Their low center of gravity effectively reduces the risk of tipping or tipping during transport. Conventional trailers, on the other hand, typically have lower load capacities and, due to their high-bed design, present certain limitations when transporting taller cargo.

Hangzhou Kotter Intelligent Manufacturing Co., Ltd. manufactures heavy-duty hydraulic semi-trailers and modular transport vehicles with adjustable wheelbases and hydraulic drive systems, adapting to the transport needs of oversized and overweight cargo, ensuring stable performance over long distances. 3. Differences in Transport Purpose

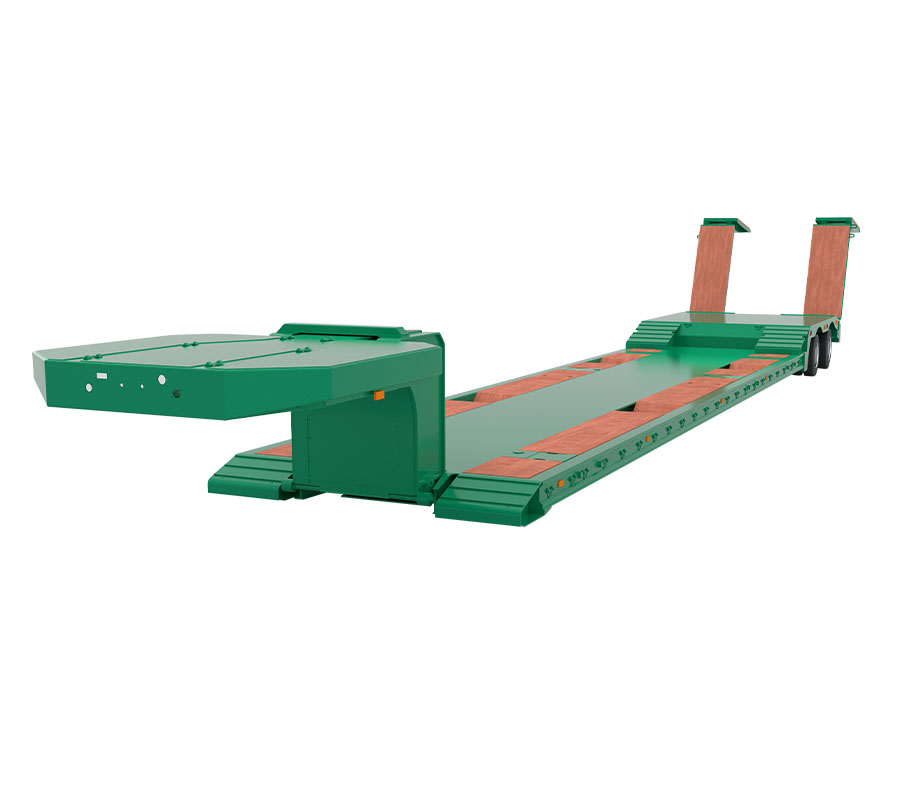

Lowloader trailers are ideally suited for transporting large machinery, heavy equipment, construction materials, and other heavy, irregularly shaped objects. They play a vital role in transporting wind turbine blades, construction machinery, precision instruments, and tower cranes. Therefore, Lowloader trailers are often used for specialized transport tasks requiring a high payload and a low center of gravity.

Conventional trailers are typically used for everyday cargo transport and are suitable for smaller, lighter loads. Their higher height makes them suitable for transporting standard containers, merchandise, and small equipment.

Hangzhou Kotter Intelligent Manufacturing Co., Ltd.'s Lowloader trailers, particularly those designed for transporting wind turbine blades, construction machinery, and precision instruments, meet the high standards of customers for specialized cargo transport. The company's innovative technology enables its Lowloader trailers to excel in a variety of complex transport environments.

Operational Ease and Safety

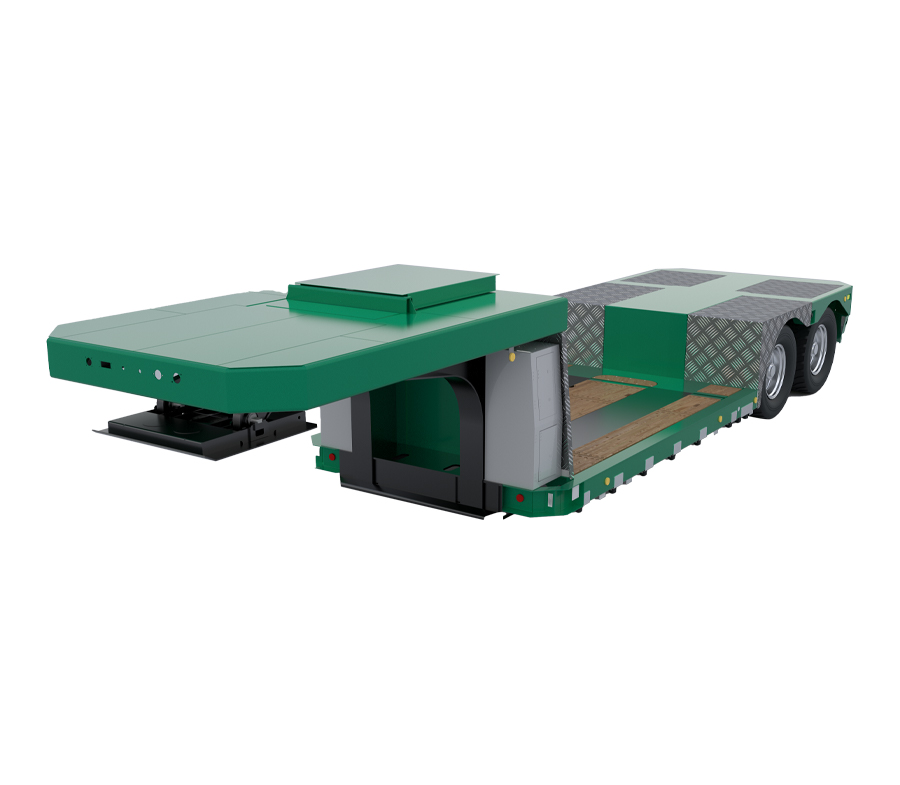

Another key advantage of Lowloader trailers is their convenient loading and unloading. Due to their low height, Lowloader trailers are often equipped with a hydraulic lift system, making loading from the ground to the trailer easy and convenient, even without the need for additional lifting equipment. This is particularly important when transporting tall, bulky, and heavy items.

In contrast, conventional trailers have higher beds, often requiring the use of cranes or other heavy equipment for loading and unloading. Therefore, Lowloader trailers offer significant advantages in loading and unloading efficiency and ease of operation, especially when transporting heavy machinery, tower cranes, and other equipment. Lowloader trailers can significantly reduce loading and unloading time.

The Lowloader trailers provided by Hangzhou Kotter Intelligent Manufacturing Co., Ltd. are equipped with an advanced hydraulic lifting system, which effectively improves loading and unloading efficiency, reduces operational difficulty during transportation, and ensures safety during transport.

What are the advantages of Lowloader trailers over conventional trailers when transporting bulk cargo?

LowloaderDesign and Efficient Loading

The design of Lowloader trailers enables them to transport larger and heavier loads than conventional trailers. The core advantage of the Lowloader design is that it lowers the center of gravity, thereby improving vehicle stability during transport. This is particularly important for transporting bulk cargo, especially tall, bulky items such as heavy machinery, construction materials, and wind turbine blades. Conventional trailers typically have a high body design. While they can carry a certain amount of weight, they have limitations when transporting overweight or oversized items. When transporting large equipment such as cranes, tower cranes, and wind turbines, Lowloader trailers provide better support and a lower center of gravity, reducing the risk of accidents during transportation.

Hangzhou Kotter Intelligent Manufacturing Co., Ltd.'s Lowloader trailers are equipped with a hydraulic suspension system, which effectively distributes the load even when heavily loaded, ensuring the vehicle does not tilt or overturn during transport. The company's products have a load capacity ranging from 60 to 150 tons, making them suitable for transporting most heavy equipment.

Enhanced Stability and Safety

Stability is a critical issue when transporting large amounts of cargo. The low center of gravity design of Lowloader trailers reduces tilting or instability caused by a high center of gravity. Conventional trailers have a high bed, which can lead to vehicle instability, especially when fully loaded. This can pose a safety hazard when navigating curves, slopes, or uneven roads. Lowloader trailers utilize multi-axle steering, hydraulic suspension, and adjustable wheelbase technology to achieve smoother transport when transporting heavy cargo, minimizing the impact of uneven road surfaces. This design not only enhances the trailer's stability but also effectively improves maneuverability.

In addition, Hangzhou Kotter Intelligent Manufacturing Co., Ltd. has incorporated an intelligent monitoring system into the design of Lowloader trailers, which monitors the vehicle's dynamic status in real time to ensure stability and safety during cargo transportation, especially over long distances or in complex terrain.

Ease of Loading and Unloading

A significant advantage of Lowloader trailers is their ease of loading and unloading. Because the bed of a Lowloader trailer is lower than that of a conventional trailer, loading and unloading cargo is much simpler. In many cases, Lowloader trailers can be loaded and unloaded directly using a hydraulic lift system, eliminating the need for additional lifting equipment such as cranes or forklifts. This significantly improves loading and unloading efficiency, especially when transporting large machinery, equipment, or construction materials, reducing the costs of manual labor and additional equipment. Conventional trailers, due to their high bed, often require external equipment to load and unload heavy cargo, which is time-consuming and costly. Lowloader trailers, with their hydraulic lifting system, offer greater ease of operation, particularly when transporting complex cargo such as wind turbine equipment and tower cranes.

Adaptability to Complex Terrain and Efficient Operation

Lowloader trailers, with their low profile, are well-suited for complex terrain. Projects such as urban construction, mining development, and wind farm construction often require transporting goods through narrow roads or uneven terrain. Lowloader trailers' multi-axle configuration and adjustable wheelbase ensure excellent maneuverability and maneuverability in diverse environments.

Hangzhou Kotter Intelligent Manufacturing Co., Ltd.'s Lowloader trailers feature advanced features such as hydro-pneumatic suspension and multi-axle steering, ensuring high stability even on uneven roads and steep slopes, ensuring smooth transport.

|

Feature |

Lowbed Trailer |

Ordinary Trailer |

|

Bed Height |

Low (usually 30-50cm) |

High (usually 80-120cm) |

|

Load Capacity |

60 tons to 150 tons |

20 tons to 50 tons |

|

Axle Configuration |

Multi-axle, supports steering |

Typically 2-4 axles |

|

Hydraulic System |

Equipped with hydraulic lifting system for loading/unloading |

No hydraulic system, external equipment needed for loading/unloading |

|

Suspension System |

Air suspension, hydraulic suspension |

Traditional leaf spring suspension |

|

Applicable Cargo Type |

Heavy, oversized, large equipment |

Regular goods, light equipment |

|

Safety |

High, low center of gravity design, anti-tip |

Lower, higher center of gravity, more prone to tipping |

|

Terrain Adaptation |

High, suitable for complex road conditions and slopes |

Low, suitable for flat roads |

What precautions should be taken when operating a Lowloader trailer on complex terrain?

Lowloader trailers, as heavy-duty transport vehicles, are widely used to transport large equipment and specialized cargo, such as construction machinery, wind turbines, and large industrial equipment. When operating a Lowloader trailer on complex terrain (such as uneven roads, steep slopes, and narrow city streets), special precautions must be taken to ensure safe and efficient transport.

Road Inspection and Planning

Before commencing a transport mission, the transport route must be carefully planned and inspected, especially in areas with complex terrain. The design of a Lowloader trailer allows it to navigate uneven roads, but detailed route planning and foresight are crucial.

Inspect road conditions: Confirm the width, slope, and curve radius of the road to ensure smooth passage for the Lowloader trailer. Road conditions are particularly complex in mountainous areas, mining areas, and urban development areas, often prone to obstacles such as rocks, mud, and potholes.

Identify elevation differences: The low center of gravity of a Lowloader trailer allows for stable operation on slopes, but steep slopes can still increase the risk of rollover. For steep slopes, assess the grade in advance to ensure smooth starting and stopping.

Evaluate narrow spaces: Lowloader trailers require a large turning radius, so when driving on urban roads or narrow streets, it's important to determine whether there's enough room to turn. This can prevent collisions or brake failure caused by turning too tight.

Hangzhou Kotter Intelligent Manufacturing Co., Ltd.'s Lowloader trailers are equipped with a multi-axle steering system and hydraulic suspension, significantly enhancing maneuverability and stability on complex roads. However, these advantages still require careful route planning and execution.

Proper Speed and Braking Control

Speed control is particularly important when driving on rough, slippery, or icy roads. Excessive speed increases the risk of loss of control, especially when turning or descending. The stability of a Lowloader trailer relies primarily on its low center of gravity and suspension system, but high speeds can still lead to an unstable driving experience.

Slowing Down: On rough, slippery, or icy roads, especially when driving downhill, it's important to slow down in advance. While the hydraulic suspension system of a Lowloader trailer provides good stability, excessive speed can still cause loss of control or damage to the cargo.

Breaking Distance: Lowloader trailers typically feature efficient air brakes, but braking distances may be extended on difficult terrain or with heavy loads. Operators should ensure adequate safety distance, especially when descending slopes or crossing bridges.

Focus on Wheelbase and Steering Control

The multi-axle configuration of a Lowloader trailer provides better load distribution, but proper steering and wheelbase control are particularly important in difficult terrain.

Multi-Axle Steering System: Hangzhou Kotter Intelligent Manufacturing Co., Ltd.'s Lowloader trailers are equipped with multi-axle steering technology, which adjusts the steering angles of different axles based on load changes, reducing wear and tear while improving cornering maneuverability. Proper steering control can effectively avoid collisions and scrapes when navigating narrow roads or around obstacles.

Wheelbase Adjustment: The variable wheelbase system of a Lowloader trailer adjusts the wheelbase based on the weight and size of the cargo, ensuring balance on uneven surfaces. Adjusting the wheelbase helps distribute the pressure of heavy loads, preventing the vehicle from losing stability on turns or slopes.

Load Balancing and Cargo Securing

Load balancing is crucial for ensuring the stability of Lowloader trailers in complex terrain. Improperly securing the cargo can cause the center of gravity to shift, affecting the vehicle's balance and even causing an accident.

Balanced Load: The hydraulic suspension system of a Lowloader trailer automatically adjusts the load, but the operator must ensure that the cargo is evenly distributed on the trailer to avoid overweight on one side. Uneven loading can lead to the risk of tipping or overturning, especially when navigating rough terrain or on curves.

Securing the Cargo: Heavy cargo often requires securing with steel cables, ropes, or specialized securing devices. Tall or irregularly shaped cargo, such as wind turbine blades or tower cranes, requires specialized securing equipment to ensure stability during transport.

Hangzhou Kotter Intelligent Manufacturing Co., Ltd.'s Lowloader trailers are equipped with advanced hydraulic securing devices and a multi-point securing system, which secure the cargo more securely to the trailer, making them particularly suitable for transporting delicate equipment or extremely heavy construction materials.

Terrain Adaptability and Intelligent Technology

The Lowloader trailer's suspension system and intelligent technology provide greater adaptability in complex terrain. For example, the hydropneumatic suspension system adjusts the vehicle's height and stiffness in real time on uneven ground, ensuring the vehicle maintains stability even when navigating potholes.

The role of the hydraulic system: The hydraulic lift system allows the Lowloader trailer to adjust its chassis height according to terrain changes, helping it to smoothly navigate ramps, obstacles, and deep trenches. This technology is particularly important for Lowloader trailers, which frequently navigate mining areas, construction sites, and urban development.

English

English  中文简体

中文简体